39 plate heat exchanger piping diagram

MASTER DETAIL TITLE PLATE AND FRAME HEAT. EXCHANGER PIPING DIAGRAM. HVAC DEPARTMENT. DATE. 08-01-12. REV DATE FILE NO. TEMPERATURE TRANSMITTER W/.1 page Piping and Instrument Diagram Standard Symbols Detailed Documentation provides a standard set of shapes & symbols for documenting P&ID and PFD, including standard shapes of instrument, valves, pump, heating exchanges, mixers, crushers, vessels, compressors, filters, motors and connecting shapes.

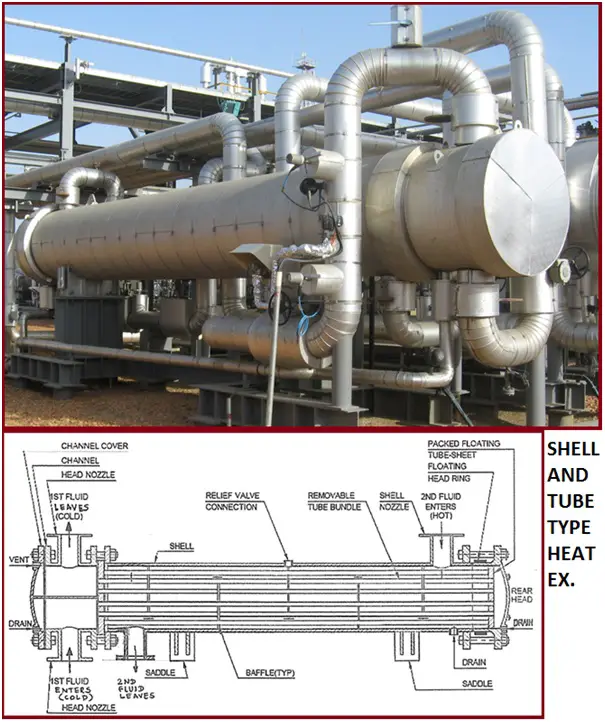

The ultimate aim of this report is to design an Air Cooled Heat Exchanger, preferably of shell and tube type, that can be used to transfer the heat energy generated in the windings of 3-phase Induction motor working at 800 rpm (Assumed). Following figure details the boundary conditions for the heat exchanger. Specifications:

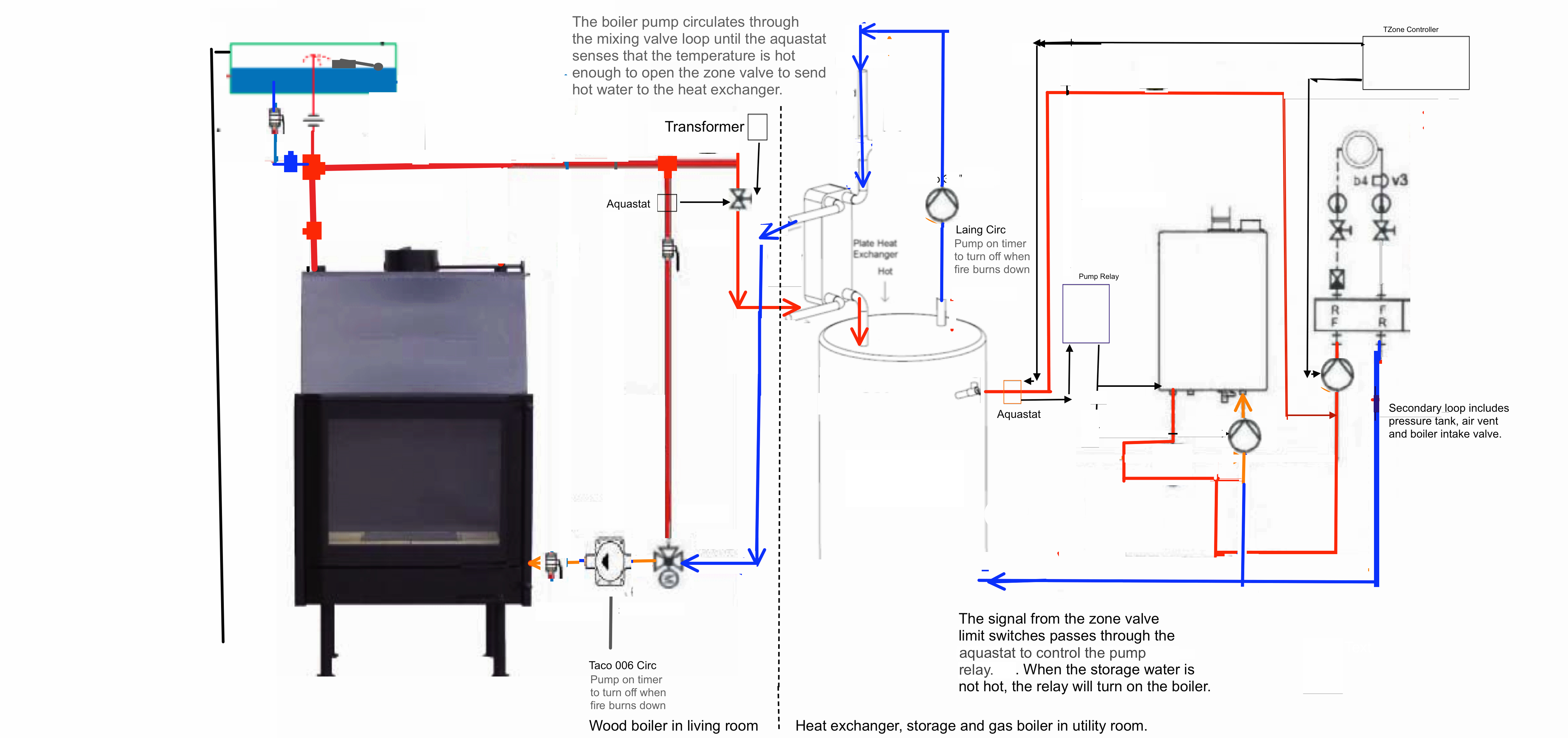

Plate heat exchanger piping diagram

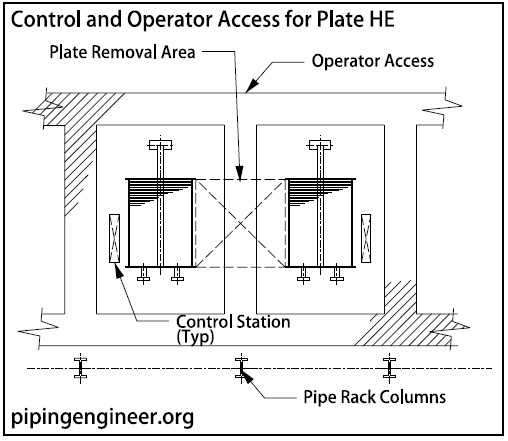

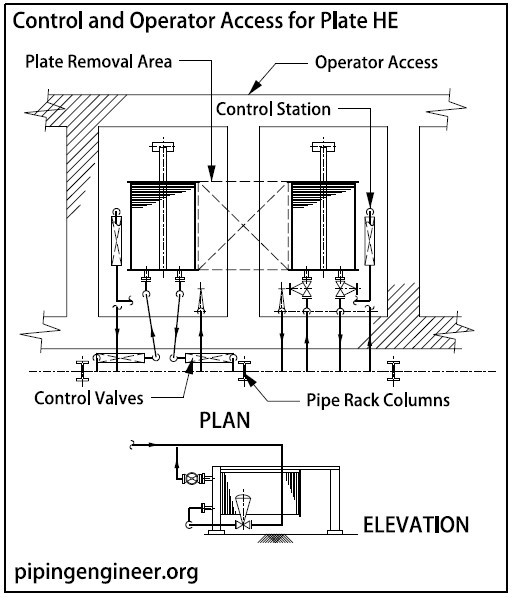

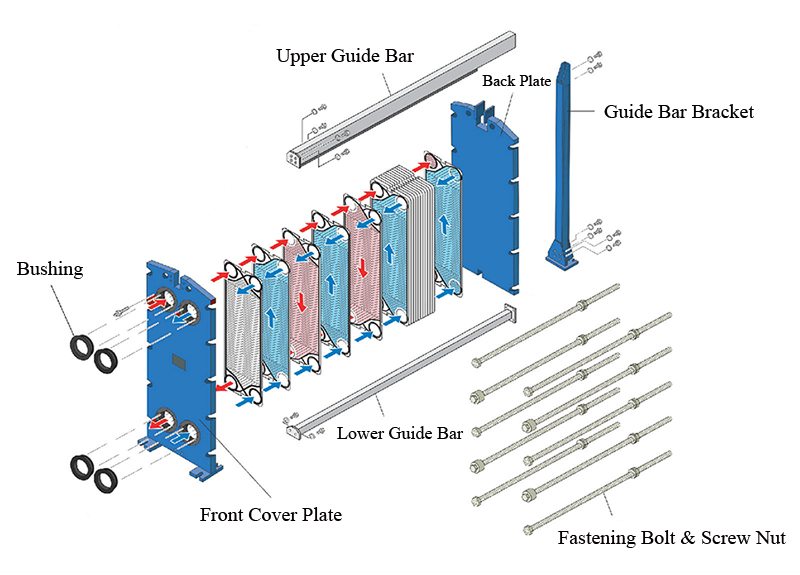

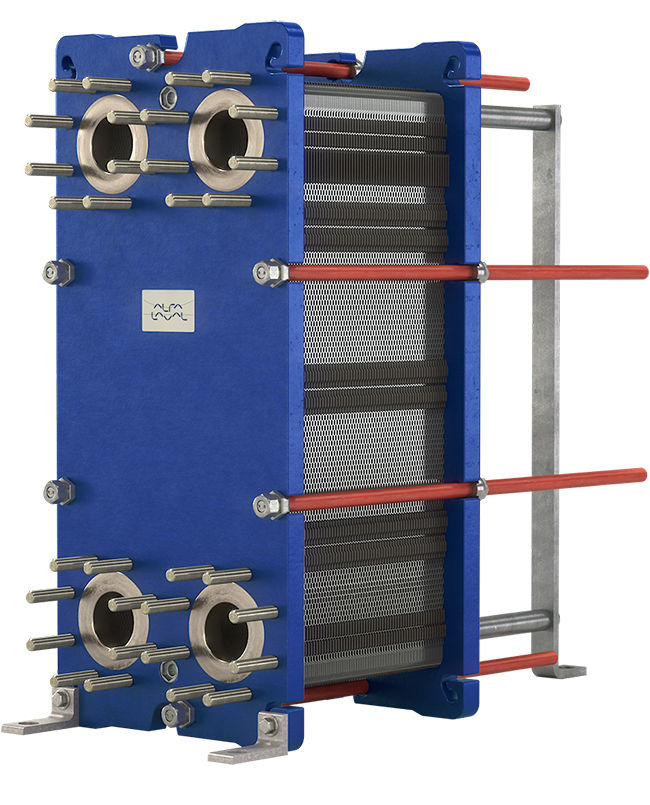

Plate Heat Exchanger Piping ... Piping is positioned to allow the opening of covers and removal of plates. Controls are located at the front and on one side for ... Check that connection piping can be removed to perform service. • Make sure that there is enough space to remove plates on one side of the plate heat exchanger. Heat Exchanger Design Handbook. Matt Pennington. Download Download PDF. Full PDF Package Download Full PDF Package. This Paper. A short summary of this paper.

Plate heat exchanger piping diagram. E-Classic. E-Classic 1450 with 1 Pump; E-Classic 2400 with 1 Pump; E-Classic 2400 with 3 Pumps; E-Classic 3250 with 2 Pumps; E-Classic Furnace and Foundation Dimensions Both sensible and latent heat may be transferred. Latent heat when moisture in the outlet air condensates in the heat exchanger. The moisture is not transferred. Cross Flow Heat Exchangers. In a cross flow heat exchanger - heat is transferred directly from the outlet air to the make-up air through the separating walls in the heat exchanger. When & why to use Plate Heat Exchangers (PHE's). - Benefits that many heating engineers often overlook. - How PHE's work ... Design/installation Diagrams.41 pages 15 Year Aluminized Steel Heat Exchanger Warranty 25 Year Stainless Steel Heat Exchanger Warranty Condenser Coil Guards Interior Corrosion Protection Polymer E-Coated Coils - 5 Year Warranty Stainless Steel Coil Casing Stainless Steel Drain Pans

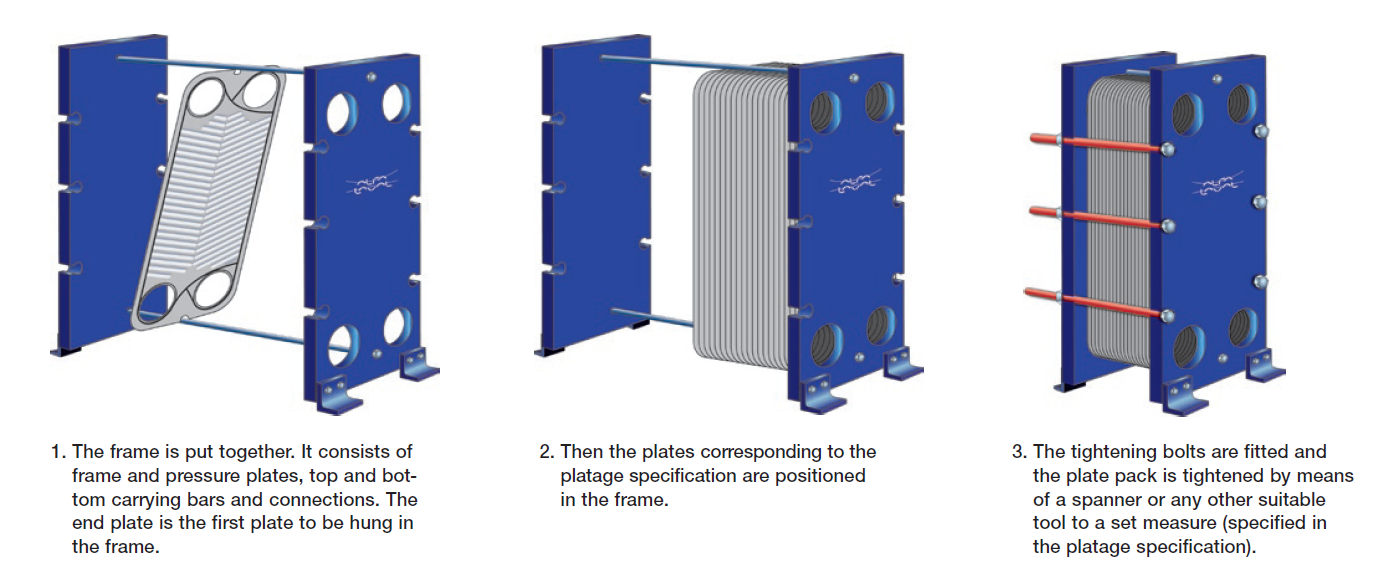

The double pipe heat exchanger is one heat exchanger pipe inside another larger pipe for either counter flow or parallel flow pattern. The heat exchange duty a llows calculation of the log mean ... Ask for an expert to perform piping and wiring work with the. Assembly Drawing and Wiring Diagram. If inexperienced worker performs piping / wiring work ...20 pages The dimension drawing includes the outer dimensions as well as type, size and position of the piping connections. The circuit diagram shows the specific ...28 pages Connections. Holes matching the piping lead through the frame plate, permitting the media to enter into the heat exchanger. For smaller connection sizes, ...35 pages

WMBP heat exchangers are not compatible with steam applications nor ... Piping Connections . ... brazed together, with every second plate inverted to.12 pages Heat Exchanger Design Handbook. Matt Pennington. Download Download PDF. Full PDF Package Download Full PDF Package. This Paper. A short summary of this paper. Check that connection piping can be removed to perform service. • Make sure that there is enough space to remove plates on one side of the plate heat exchanger. Plate Heat Exchanger Piping ... Piping is positioned to allow the opening of covers and removal of plates. Controls are located at the front and on one side for ...

![Typical plate heat exchangers [15]. | Download Scientific ...](https://www.researchgate.net/profile/Zahid_Ayub/publication/244588426/figure/download/fig1/AS:393258791391232@1470771610364/Typical-plate-heat-exchangers-15.png)

![Schematic of a plate heat exchanger [47]. | Download ...](https://www.researchgate.net/profile/H_Jouhara/publication/324811679/figure/fig11/AS:630480231731209@1527329609380/Schematic-of-a-heat-pipe-69_Q320.jpg)

Komentar

Posting Komentar