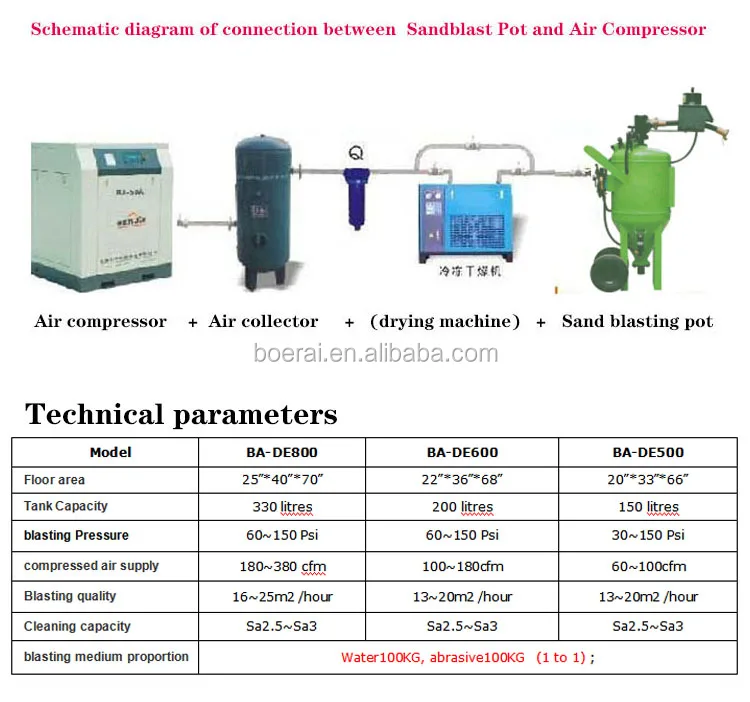

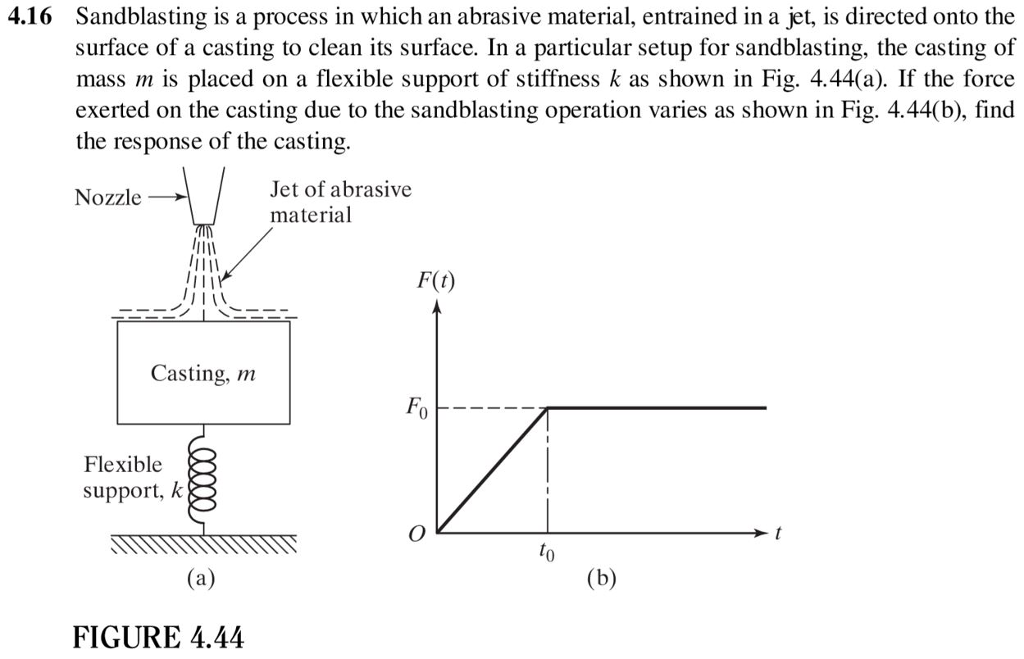

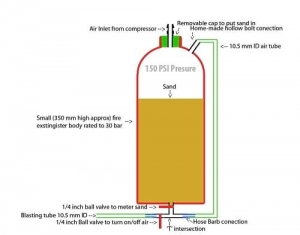

41 sandblasting setup diagram

Clemco Classic Blast Machine Model 1648 HP Package is a High Pressure Breathing Air System, Portable, 3 cuft - 300lbs., with 1-1/4 inch Piping. The 3 cuft HP classic blast machine holds 3 cubic foot (approximately 300 lbs.) of abrasive blast media. This portable blast machine has 1-1/4" piping and comes with a Flat Sand Valve (FSV) and remote ... Sandblasting is the best and only real way of removing paint and rust that insures your metal is properly prepped for a long lasting paint job. Rust neutralizers, Paint-over-rust products, wire brushing, nothing works to really get into the metal and deep clean like sandblasting. The following is everything I have learned about the subject ...

Sandblasting Material Guide December 12, 2018. Sandblasting is an extremely useful procedure in a broad array of applications and industries. Whether a material needs to be cleaned, deburred, prepped for powder-coating, de-rusted, shot-peened or otherwise just have its paint removed, sandblasting is the process for the job.

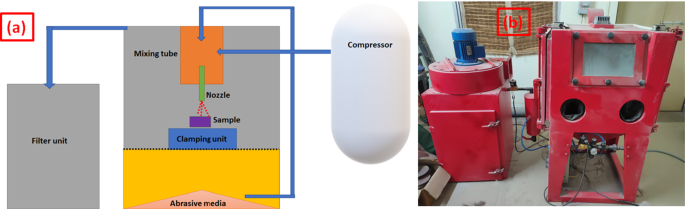

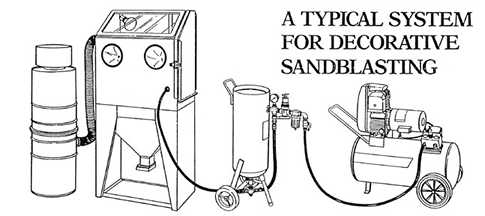

Sandblasting setup diagram

Sandblasting Room Preparation and Requirements. Abrasive blast systems depend on modern, well-designed blast rooms to ensure a confined, controlled, and clean environment for abrasive recycling. Whether removing an existing coating or prepping a surface for a new coating, optimal surface preparation with the use of air compressors is crucial. Blasting is the process where small angular or spherical particles are propelled at a part by compressed air, or mechanical high speed rotating wheels or water pumps . The blast media type, shape, size, density, and hardness, along with media acceleration A quick start guide to setting up a Clemco Classic Blast Pot. Free Shipping on Clemco Blast Machines: https://sandblastingmachines.com/classic-blast-machine...

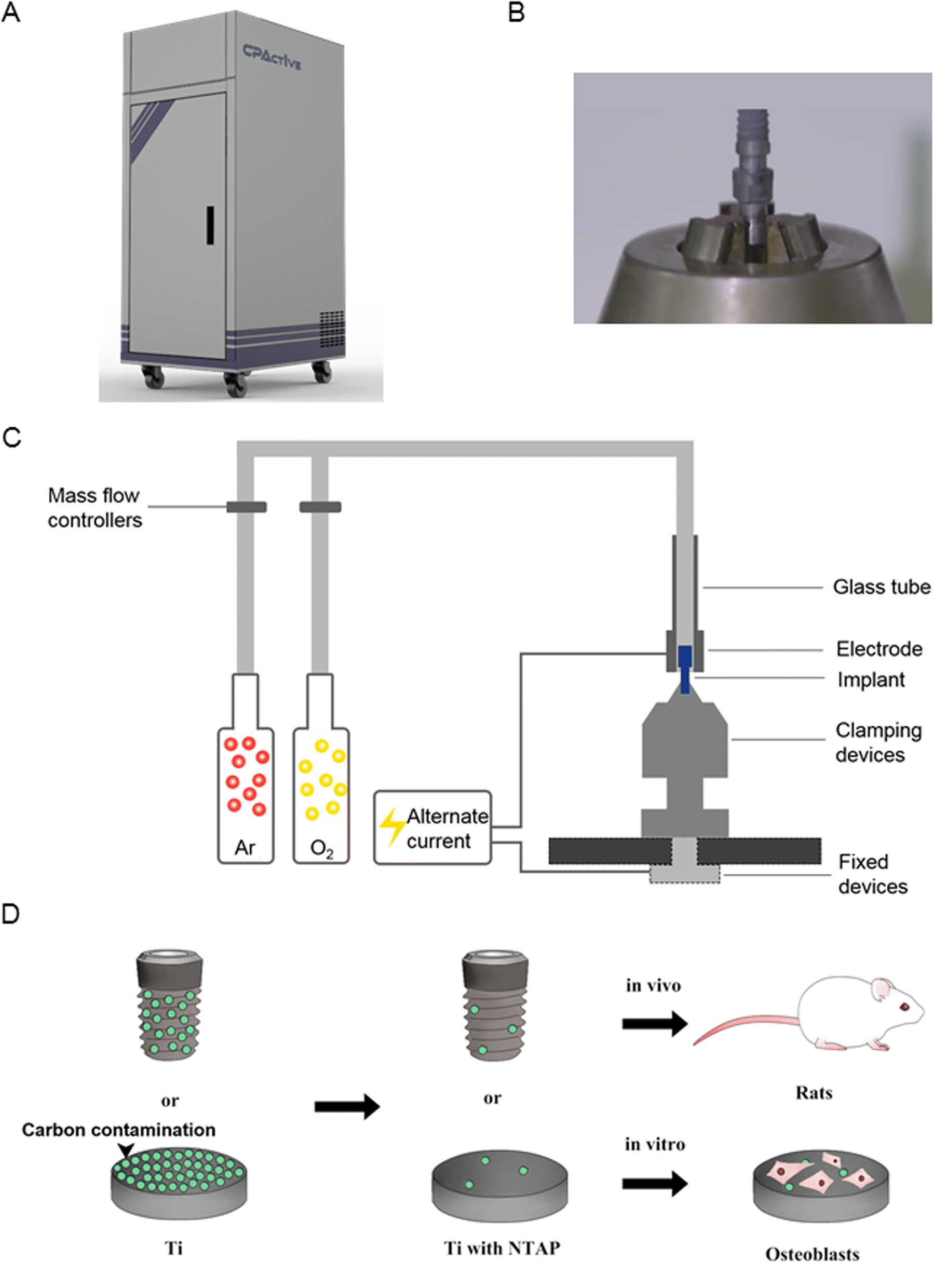

Sandblasting setup diagram. A really well-maintained sandblasting system depends on the proper functioning of many different components, so we have filled our inventory with a large variety of devices and accessories for your examination. We have a broad range of sandblast guns as well as an array of nozzles including Venturi and straight bore types. Furthermore, we carry ... Sandblasting Setup and Application. May 8, 2019. Sandblasting is a conventional method of preparing a metal substrate and material surfaces before applying a treatment, coating or other finishes. Whether you’re looking for an economical process of stripping paint, deburring, cleaning, bright finishing, scale removal, shot peening or adding ... The versatile air compressor can successfully be used for sand blasting . Sandblasters are used to clean difficult substances like rust or paint from solid surfaces like metal. A sandblaster can make a huge sanding job suddenly simple. To get the best performance from your sandblaster, you need to select the right compressor for the job. Econoline Product Manuals. 24-0 BB _ 36-0 B - LED. 24-0, 30-0, 36-1,48-2 LED. 42 x 24, 48 x 24 FT -LED. 40x4048x4860x4860x3060x60-LED. 48 X 36 RH HZ DOOR-LED. 48 X 36 RH VERT DR-LED. 100 CFM BAG DC 110V. 100 cfm cartridge 110v _ 220V dc.

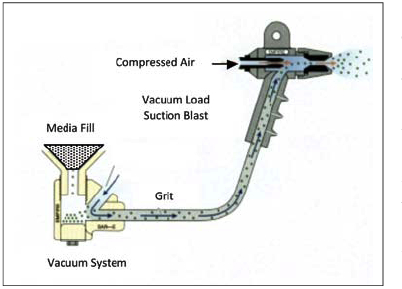

Burkey Sandblasting - No Job Too Big or Small. Burkey Sandblasting has been serving the Grand Junction area for over 30 years - providing quality sandblasting services for home and business. No job is too big or small. From lawn chairs to tractors trailers, we like doing it all. Auto restorations are our specialty, we're classic car buffs ... The setup is a normal air gun, with a hose at a second attachment. This sucks in sand at a constant rate, via Bernoulli's Principle, like an aspiration setup in a chemistry class. Find a bucket of sand for the hose to rest in. Find some good method to keep the hose submerged in sand, like duct-taping the hose to the side of the bucket so that it's always pointed downwards. Recommended Set-up 5 General Description of Blasting 5 Intended Function Of Equipment 6 Typical Layout 6 Product Variants 7 Key Parts & Controls 7-8 How the System Works 8 ... Initial Set-Up And Routine Checks 13 Parts diagrams for valves 14-17 Trouble Shooting / Fault Finding 18 Name And Address Of Manufacturer 19 . www.sfeg.co.uk Sandblasting operations can be overlooked when preparing safety plans because they are generally a small part of a larger project such as cleaning and refinishing or painting. As a result, many workers are exposed to the hazards of sandblasting without adequate protection. Even if all sandblasting equipment is properly designed and regularly inspected, users must always be alert to the hazards ...

For wet blasting, you can use any abrasive as long as it is clean, consistent, and sinks in water. The most inexpensive and popular choice of media is 40/70 recycled bottle glass. You can purchase media in the Online Store, or buy it locally to save on shipping costs. Properly using a sandblaster ensures your safety while sandblasting and improves the results you will get while sandblasting. In many ways the actual use of the sandblast pot or sandblast cabinet are easy to understand. However for maximum results when using a sandblaster, it is important to understand proper equipment setup, safety equipment requirements, and a few details about proper ... Footswitch Operated Sandblasting System: My (ex-wife) has a sandblasting setup that she bought about 2010 to start her own business. She does mostly glass engraving but wanted to also be able to do wood and stone products. The grit that she uses is very expensive and would be ruined if it … Along with a simple solution and diagram showing you what the problem is inside. Sandblasting Safety Guide: A much needed industry guide to talk about safety, silicosis prevention, and safety gear with sources. Download my sandblaster plans and extra bonuses today for Only $17!

can now set up our blasting equipment. Position the compressor upwind from the work area so that airborne grit does not enter the cooling or air intake systems. The compressor should be level so that the oil and moisture separators can function effi-ciently. The power unit’s lubrication system also depends on the compressor being level.

1 Jul 2018 — How to set up a sandblasting cabinet, specifically, the RB4226 model from Raptor Blasting Systems, the perfect blast cabinet for small to ...

Inevitably, the parts inside your blasting cabinet, pressure blaster and blasting gun will wear out after a certain amount of use. The good news is that we carry a variety of replacement parts for media blasting. Use these accessories to do standard maintenance and repairs or upgrade your setup for even more effective parts cleaning.

This guide explains the construction and setup of vapor blasting cabinets, with additional information and diagrams to assist readers in constructing their own. 34 pages of information, images and illustrations on converting sandblasters and other recyclable appliances. Includes nozzle, pump and agitation jet mounting diagrams.

Our first sandblast cabinet was set up to use a siphon system to deliver the sand. That method uses much more compressed air, so you need a bigger compressor, or you have to wait while your air catches up with the blaster. You can see that it has two protective gloves in the front of the cabinet and a door on the side to put the glass into the ...

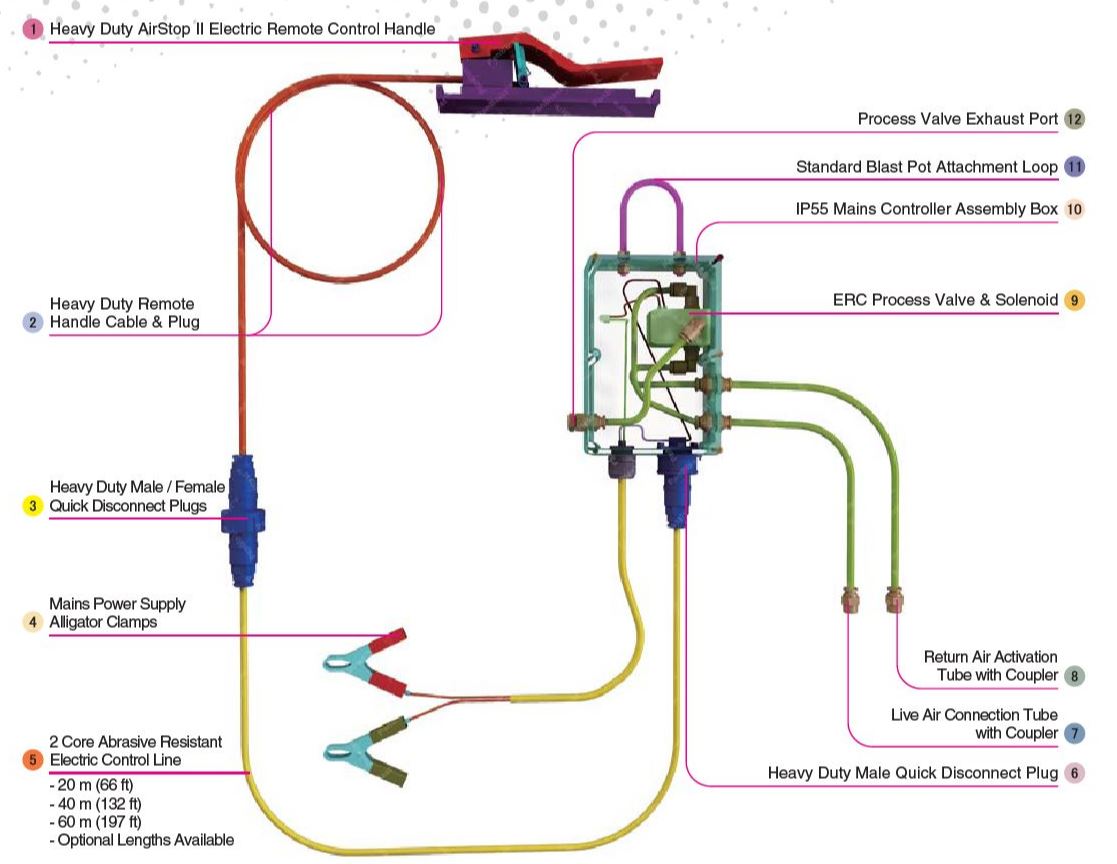

Obsolete Equipment Parts Book. Portable Systems & Parts Book. APF 3100 - Respirator Air Filter Cartridge. Automatic Air Valves. Safe-Stop II Remote Control Handles Spare Parts. EM 2-2 & EM 2-4 Replacement Spare Parts. Automatic Sure-Flo Regulators Parts. Sure-Flo Media Regulators Parts.

Sandblasting Air Connections and Setup. The Compressor Pressure Gauge reads storage tank pressure Pressure Switch ... This Diagram shows the “starting position” for all valves when setting up a pressure pot. ... Sandblasting Air Connections.ppt

Sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. It can be used for cleaning, deburring, removing paint and coatings, shot-peening, and/or other methods for finishishing or improving the surface on a number of different materials.

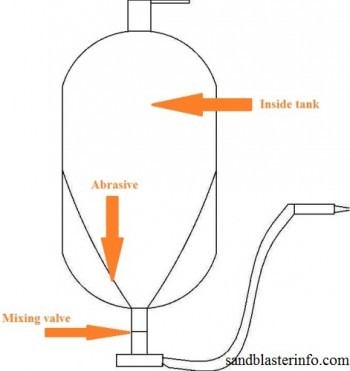

Also, for anyone’s information, the plans on my site are for pressure pot modifications to fix abrasive flow problems . So if you’re looking to make your own pressure pot sandblaster, I included this video to show you an example of the anatomy of how it’s setup. If playback doesn't begin shortly, try restarting your device.

Air Pressure Blasting: Air pressure blasting uses compressed air to apply abrasive ~o a surface. Air pressure blastL~g uses either a direct pressure or an induction method that may use either the siphon or gravity nethod as follows: 1.1.2.1 Direct Pressure Method: In direct air pressure blasting,

Sandblasting equipment tutorial set up guide. Our easy set up guide for sand and shot blasting equipment Also check out our pdf guide to blast cleaning .....

This manual provides critical safety instructions on the proper setup, operation, maintenance, and service of this machine/tool. Save this document, refer to it often, and use it to instruct other operators. Failure to read, understand and follow the instructions in this manual may result in fire or serious personal injury—including amputation,

A quick start guide to setting up a Clemco Classic Blast Pot. Free Shipping on Clemco Blast Machines: https://sandblastingmachines.com/classic-blast-machine...

Blasting is the process where small angular or spherical particles are propelled at a part by compressed air, or mechanical high speed rotating wheels or water pumps . The blast media type, shape, size, density, and hardness, along with media acceleration

Sandblasting Room Preparation and Requirements. Abrasive blast systems depend on modern, well-designed blast rooms to ensure a confined, controlled, and clean environment for abrasive recycling. Whether removing an existing coating or prepping a surface for a new coating, optimal surface preparation with the use of air compressors is crucial.

Komentar

Posting Komentar